(Almost) 50 years with Peter Wiggins

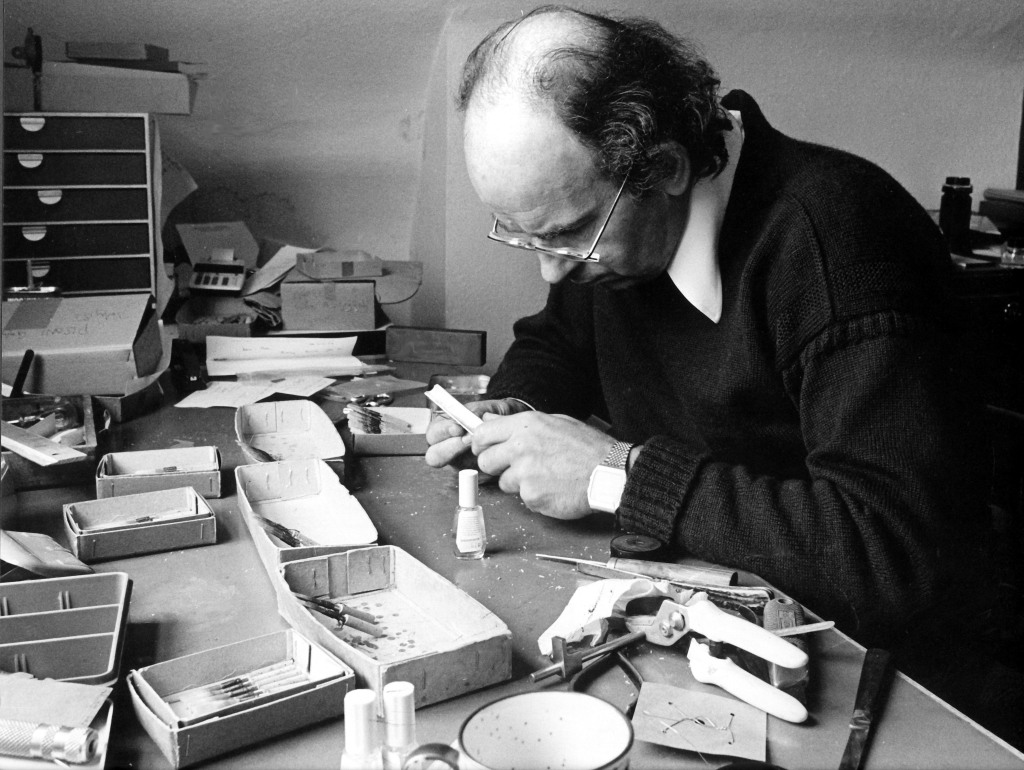

Paul Harris, Business Development and Relationship Manger at Howarth of London chatted with Peter Wiggins during lockdown, discussing his long association with Howarth.

Do you remember how you agreed to make reeds for us? How does it feel to have been making reeds for Howarth for over 47 years?

Having become dissatisfied with my life as a management consultant, constantly on the move, I decided to change direction completely and so I quit.

I had made reeds for myself for a long time, instructed mainly by my teacher, Stephen Nagy, in many of the mysteries and techniques of reed making. So I decided to try this commercially.

I started out as a reed maker in October 1974. My partner Ann Greene, (now Wiggins), a professional oboe player and teacher, introduced me to many of the teachers she knew, to help get my business off the ground. In less than a month, Nigel Clark had spotted me as a new prospect and, after a bit of hesitation on my part, he signed me up. Now, getting on for 50 years later, I look back on my long association with Howarth with gratitude and satisfaction. I already had quite a few private clients, both at home and internationally, but Howarth had early on become a mainstay of my work, and for many years occupied about half of my output.

How have we (Howarth) changed over that time?

My small business grew rapidly but Howarth grew even more quickly. Its factory became even more substantial and sophisticated, but the personal friendliness and cooperation remained a central feature of the firm. These aspects were and still are very important to me.

Is there a normal day or process you go through? What’s a normal day for a reed-maker?

I can really only speak for myself about the normal day of a reed maker and the processes gone through. For many years I used to work 10-12 hours a day, (I finished with The Archers!). Much of the work is routine – cane splitting, gouging, shaping, tying-on and various stages of scraping. Close measurements are vital throughout many of these stages.

When I first started out, I did all the scraping by hand, but relief came when profilers became available. I use three of them, all old, to do slightly different processes. For example, one machine does the main 10-11mm scrape, and another concentrates on the tip. I believe modern designs of profiler combine these functions in one single machine. No matter how careful the measurements and profiling are, reeds emerge with different features, good and bad. The interesting phase is to adjust and modify the reed to get the desired result. This is the interesting part of the job!

Has your reed style changed over time?

My reed style has remained pretty constant over all these years – a European scrape of 10-12mm with a short and very thin crescent tip, thick heart and tapered sides. I gouge the cane to about 0.57mm. The main difference between my reeds and the bulk of European reeds is that I wire them. This gives stability and allows for softer reeds and a predictable aperture. The downside is that responsiveness is reduced and then this has to be compensated for.

Graham Salter has written a wonderful and comprehensive book, some 500 pages long, about all aspects of the oboe reed. So I have a problem to say anything useful, in a couple of paragraphs!

Do you feel customer expectations have changed over time?

I don’t think customer expectations have changed that much over the years. Beginners want a reed that blows easily, (and their teachers would also like them to play in tune!). Experienced players like responsive reeds that help produce the sort of sound they want. These aims can conflict with one another, and balancing the reed is the tricky part.

What advice do you have for the next generation of oboists and reed-makers?

Advice for new potential reed makers? Think hard if you wish to do reeds commercially. Competition is pretty stiff, and the hours can be long. I have found it rewarding, but a craftsman is never rich!

Explore Wiggins Reeds on our website here.

We would like to thank Peter for working with us for the last 47 years and hope for many more!